Expert of Systematic Overall Solution for Calcium Material Resource Utilization

-

ProductPioneer In Calcium Material Industry Services, Renowned Globally For Exceptional Quality.Marketing & ServiceNational Service Hotline:

-

SolutionEngineering Service Provider Empowering New Technologies For Calcium Carbonate.Marketing & ServiceNational Service Hotline:

-

CaseExperts In Calcium Stone Industry Engineering With A Deeper Understanding Of Craftsmanship.Marketing & ServiceNational Service Hotline:

-

InnovationSurvive By Quality, Develop Through Innovation.Marketing & ServiceNational Service Hotline:

-

BlogsPeople-Oriented, Advocating Technology, Customer First, Win-Win Cooperation.Marketing & ServiceNational Service Hotline:

-

AboutInnovator In Calcium Materials Industry, Global Service Leader.Marketing & ServiceNational Service Hotline:

Comprehensive service provider for full-process calcium material production line

Our solutions are future-oriented, dedicated to planning and building efficient, intelligent, green, digital, and energy-saving factories.

了解更多 →

World professional equipment enterprise group

Leading the development of the calcium material industry

World professional equipment enterprise group

Ensuring the safety of your project

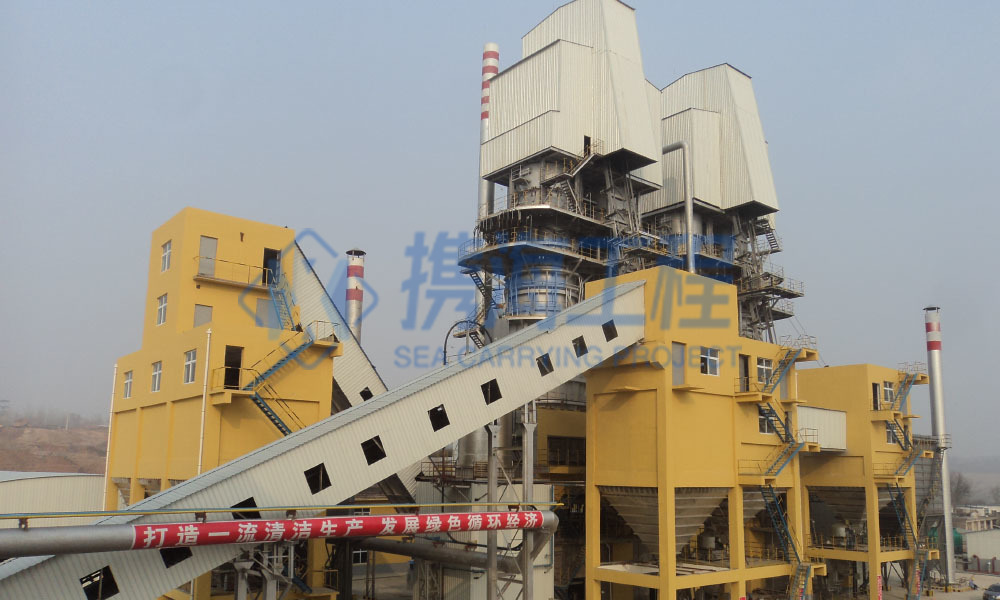

Xiehai Engineering has long focused on the production and manufacturing of metallurgical machinery and equipment, as well as the design and research and development of production lines for calcium carbonate and its deep processing series products.

了解更多 →Ca²⁺

2+

WHO WE ARE

Calcium stone industry integrated service provider

Green And Low-Carbon Pioneer In The Industry Defining A Better Quality Calcium Material Production Method

OUR SOLUTION

Green recycling calcium engineering pioneer, one-stop overall solution service provider

Its core component is a two-layer burner beam. Several fuel pipes inside the beam supply fuel to the burners, which are distributed on both sides or the bottom of the beam. This ensures that the fuel is evenly distributed across the kiln's cross-section, guaranteeing uniform combustion across the entire vertical kiln cross-section.

A mining crushing line, also known as a crushing production line, is a combination of specialized equipment used for producing sand for construction and stone materials for metallurgy and chemical industries. It is mainly used for processing rocks such as limestone, basalt, and granite.

The new vertical drying production line adopts our company's patented technology for a unique internal structure design, achieving full contact between the material and hot flue gas during the drying process. This allows for a multi-stage heat exchange through deflection, resulting in uniform heating of the material and high thermal efficiency. The carbon material moves in a peristaltic manner through the annular space between the inner and outer cylinders, with the materials almost in a stationary state, effectively reducing the wear and damage rate between the materials.

The new type of powder production line for coal powder preparation consists of a raw coal storage and transportation system, a grinding system, a powder collection system, a flue gas furnace system, and an electrical and instrumentation automation system. It is widely used in industries such as cement, electricity, steel, and metallurgy.

In the process of planning and designing the production line, it is important to make reasonable use of the site, comprehensively balance various resources and needs, and reduce the occupied area.

The humidifying and mixing production line is a type of equipment used for humidifying and mixing industrial powders. Its working principle mainly includes three aspects: humidification, mixing, and control.

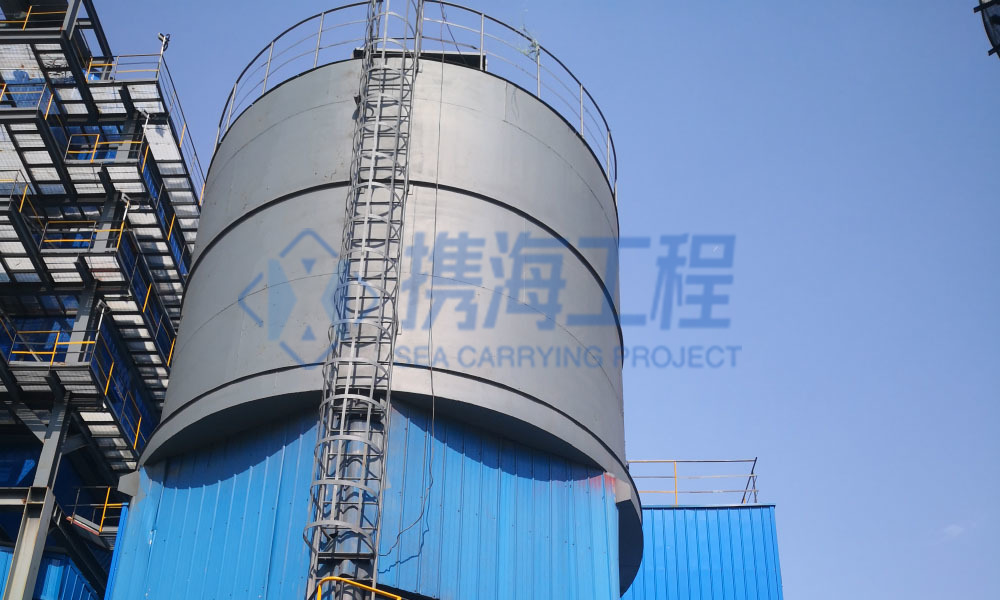

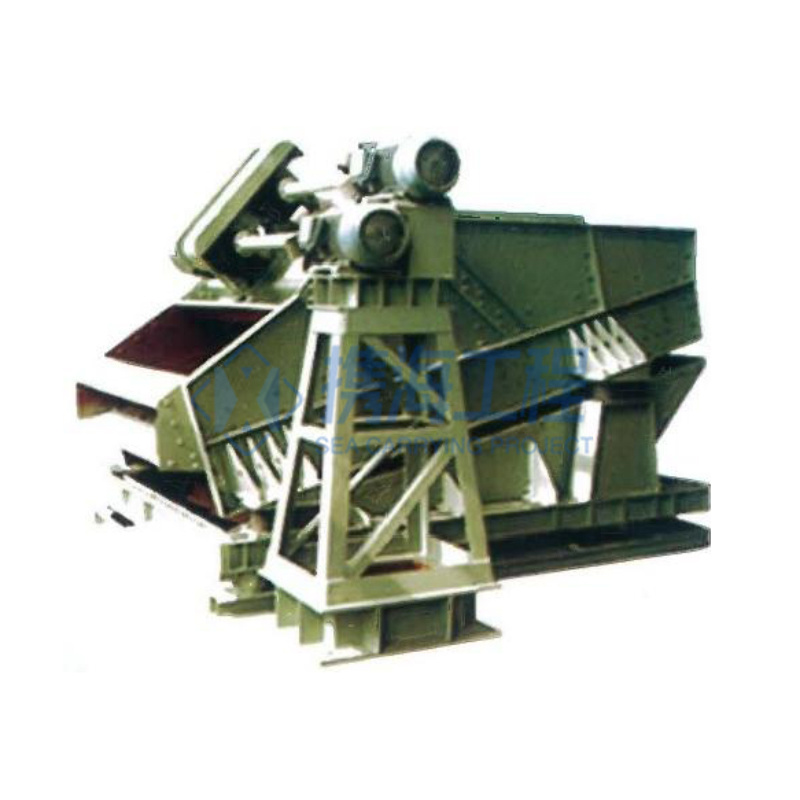

The production line is centered around large tension screens, banana screens, or linear screens, complemented by auxiliary facilities such as storage silos, drag belt scales, belt conveyors, bucket elevators, and environmental dust collectors. It is reasonably planned and arranged according to the actual site conditions of the customer, ultimately forming an intelligent and environmentally friendly material screening and processing system.

ABOUT XIEHAI

Hebei Xiehai Engineering Technology Co., Ltd.

The company focuses on the four major areas of industrial engineering, equipment manufacturing, calcium material research and development, and energy conservation and environmental protection, with R & D and design, manufacturing, and general engineering contracting as its core business, building an efficient service system to meet the diverse needs of customers. Uphold win-win cooperation, join hands with partners from all walks of life. Its business network extends from domestic to global, its business goes deep into the core of many industries, its market share and industry influence have jumped simultaneously, and it is steadily moving towards a global professional engineering and technical service provider, creating a brilliant chapter for Chinese enterprises.

Workshops & Equipments

VR

Qualifications and Honors

Video Center

2020

40%

150+

100+

PROJECT CASES

Calcium Materials Industry Innovator, Global Service Leader

Dec 27,2025

Are High Efficiency Furnace Filters Worth the Investment? A Comprehensive Guide

Dec 20,2025

Understanding Conveying Equipment: A Comprehensive Guide for Industrial Applications

Dec 13,2025

How Weather Conditions Affect the Performance of Drying Equipment: A Comprehensive Analysis

Dec 09,2025

Advanced Vibrating Mining Screens for High-Efficiency Material Separation

Dec 09,2025

High-Performance Vibrating Screen for Efficient Industrial Material Separation

Dec 06,2025

The Essential Guide to Dust Removal Equipment in Industrial Applications

Nov 29,2025

Choosing Between Static and Dynamic Humidifying Stirring Equipment: A Comprehensive Guide

Nov 24,2025

Vibrating Screen: Efficient Material Separation and Grading for Industrial Applications

Nov 22,2025

Understanding Mining Vibrating Screens: A Comprehensive Guide for Professionals

Nov 21,2025

Nov 20,2025

Understanding Conveying Equipment: Key Components and Applications in Industrial Settings

Nov 19,2025

Exploring Different Materials Used in Drying Equipment Design

CONTACT US

Hand in hand to create great achievements, the sea embracing all rivers cast brilliant

The sea carrying project has long focused on the production and manufacture of metallurgical machinery and equipment, as well as the design and research and development of calcium carbonate and its deep processing series product production line. With rich industry experience and professional technology, it can accurately meet the diversified needs of multiple industries and fields, provide customized solutions for various customers, and establish a good reputation and solid market position in related fields.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Telephone

Company Address

Weier Business 801, No. 92 Huai'an East Road, Yuhua District, Shijiazhuang City, Hebei Province