Expert of Systematic Overall Solution for Calcium Material Resource Utilization

-

ProductPioneer In Calcium Material Industry Services, Renowned Globally For Exceptional Quality.Marketing & ServiceNational Service Hotline:

-

SolutionEngineering Service Provider Empowering New Technologies For Calcium Carbonate.Marketing & ServiceNational Service Hotline:

-

CaseExperts In Calcium Stone Industry Engineering With A Deeper Understanding Of Craftsmanship.Marketing & ServiceNational Service Hotline:

-

InnovationSurvive By Quality, Develop Through Innovation.Marketing & ServiceNational Service Hotline:

-

BlogsPeople-Oriented, Advocating Technology, Customer First, Win-Win Cooperation.Marketing & ServiceNational Service Hotline:

-

AboutInnovator In Calcium Materials Industry, Global Service Leader.Marketing & ServiceNational Service Hotline:

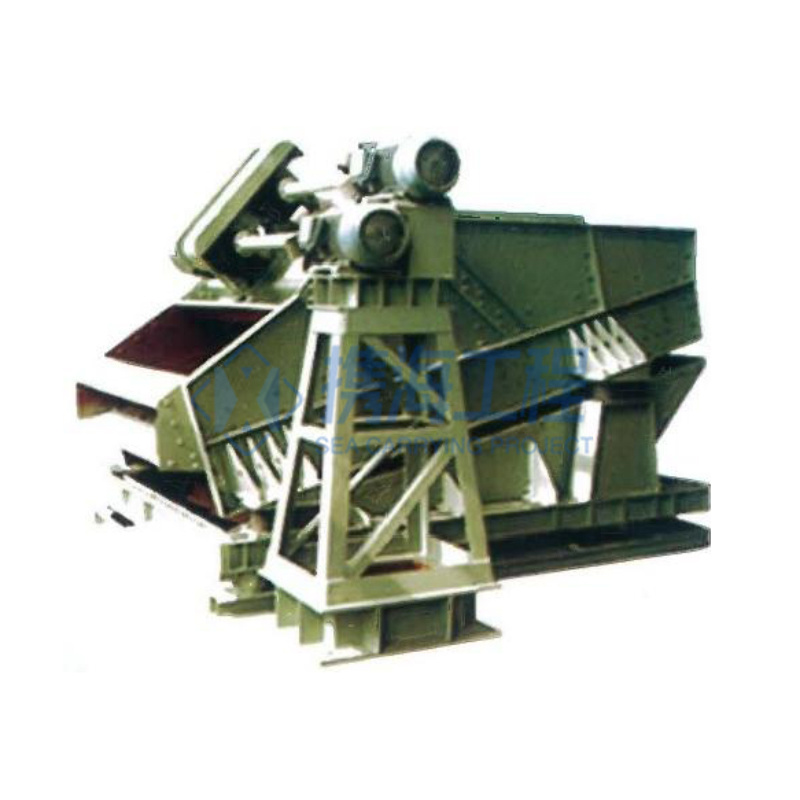

Understanding Mining Vibrating Screens: Essential Equipment for Efficient Material Processing

Nov 16,2025

One of the primary functions of mining vibrating screens is to improve the efficiency of material processing. By using vibrating screens, operators can achieve higher screening capacities, which means more material can be processed in a shorter amount of time. The vibration mechanism allows particles to move more freely, reducing the chances of clogging and ensuring a consistent flow of materials through the screen.

There are several types of mining vibrating screens, including linear vibrating screens and circular vibrating screens. Linear vibrating screens feature a linear motion that provides a straight-line flow of material, making them ideal for dry materials and applications where separation of fine particles is essential. On the other hand, circular vibrating screens utilize a circular motion, which helps in the stratification of materials, allowing for better separation of heavier particles from lighter ones.

When selecting a mining vibrating screen, it is important to consider design factors, such as screen surface material, mesh size, and screen deck configurations. The screen surface material affects the durability and wear resistance of the screen, while the mesh size determines the filtration capability and the size of the particles that can pass through. Additionally, multiple deck configurations can be utilized to achieve different separation stages, further enhancing the efficiency of the screening process.

The maintenance of mining vibrating screens is also critical to their performance. Regular inspections and maintenance routines can help identify potential issues before they escalate, ensuring that the screens operate at their optimal capacity. Components such as motors, springs, and screen media should be regularly checked and replaced as necessary to minimize downtime and maintain productivity.

In conclusion, mining vibrating screens are essential tools for the effective processing of materials in the mining industry. By understanding their functionality, design considerations, and maintenance needs, industry professionals can enhance efficiency, reduce operational costs, and ensure consistent material quality. Investing in the right mining vibrating screen and adhering to best practices can significantly impact overall project success.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Telephone

Company Address

Weier Business 801, No. 92 Huai'an East Road, Yuhua District, Shijiazhuang City, Hebei Province