Expert of Systematic Overall Solution for Calcium Material Resource Utilization

-

ProductPioneer In Calcium Material Industry Services, Renowned Globally For Exceptional Quality.Marketing & ServiceNational Service Hotline:

-

SolutionEngineering Service Provider Empowering New Technologies For Calcium Carbonate.Marketing & ServiceNational Service Hotline:

-

CaseExperts In Calcium Stone Industry Engineering With A Deeper Understanding Of Craftsmanship.Marketing & ServiceNational Service Hotline:

-

InnovationSurvive By Quality, Develop Through Innovation.Marketing & ServiceNational Service Hotline:

-

BlogsPeople-Oriented, Advocating Technology, Customer First, Win-Win Cooperation.Marketing & ServiceNational Service Hotline:

-

AboutInnovator In Calcium Materials Industry, Global Service Leader.Marketing & ServiceNational Service Hotline:

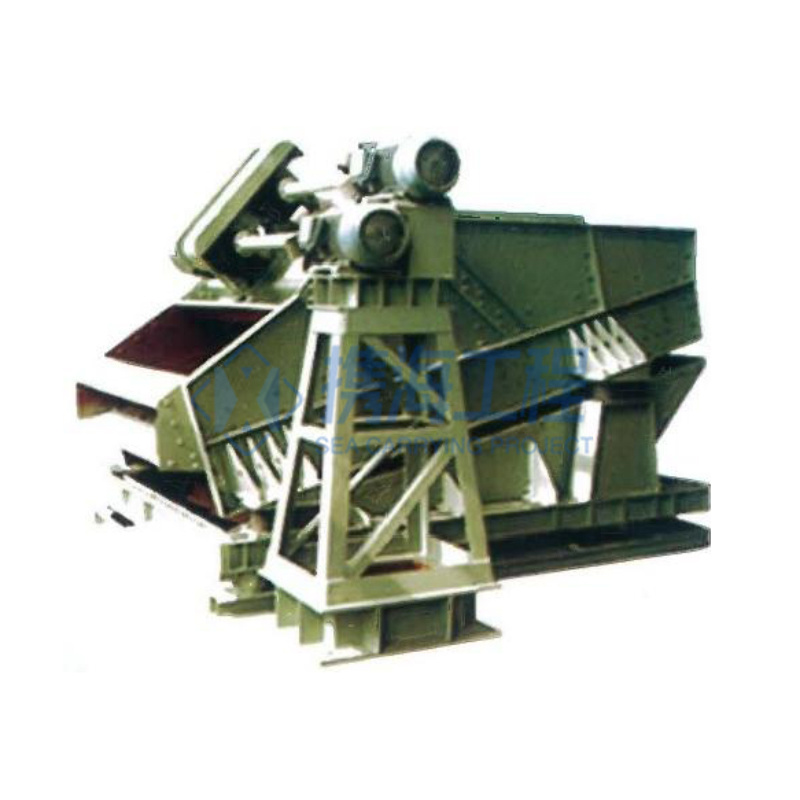

Bucket Elevator: The Secret Weapon for Increased Efficiency

Jul 05,2025

Basic Concept of Bucket Elevators

In modern industry, Bucket elevators as an important conveying equipment, with its material lifting capabilities, are widely used in various production lines. Its working principle is very simple, using a series of bucket-shaped containers to lift materials from a low place to a high place, it's like easily sending heavy items to the top of a peak.

Working Principle of Bucket Elevators

The core of a bucket elevator lies in its "buckets." These buckets are usually made of sturdy materials that can withstand the weight of the material. During the lifting process, the buckets are constantly connected to chains or belts, forming a closed loop. Imagine a constantly rotating wheel; as long as you put the material in, it will "send" the material to the height you want.

Advantages of Bucket Elevators

- **High efficiency**: Able to quickly lift a large amount of materials, saving manpower and time.

- Small footprint: Compared to other lifting equipment, bucket elevators have a more compact design.

- Versatile: Suitable for powders, granules, and bulk materials, virtually all-inclusive.

Application Fields of Bucket Elevators

So, where are bucket elevators used? From food processing to mining, from chemicals to construction, they are almost everywhere! For example, in grain storage, bucket elevators can quickly lift grains from the ground to the storage warehouse, ensuring efficiency and safety.

Industry Cases

In the cement production industry, the role of bucket elevators is particularly significant. Imagine that tens of thousands of tons of cement need to be transported every day; the high performance of bucket elevators not only reduces labor costs but also greatly improves the overall efficiency of the production line, truly achieving "more with less"!

Selecting the Right Bucket Elevator

When choosing a bucket elevator, the first thing to consider is the nature of the material. Different materials have different requirements for the material and shape of the bucket. In addition, lifting height, lifting speed, and working environment are also important factors affecting the choice. If you have any doubts about the selection, you can consult a professional to ensure you choose the most suitable equipment!

Maintenance and Upkeep

Of course, owning a bucket elevator is only the first step; subsequent maintenance and upkeep are equally important. Regularly check the working condition of the chains, buckets, and motors to ensure the stable and safe operation of the equipment. Just like "a sharp knife doesn't hurt the woodcutter," good maintenance can extend the service life of the equipment and avoid unnecessary wear and tear.

Summary

In summary, Bucket elevators As an efficient material lifting equipment, it plays an indispensable role in modern industry. Whether it is selection, use, or maintenance, we need to thoroughly understand its working principle and application scenarios. In this way, we can better utilize this technology, improve production efficiency, and promote the development of various industries.

Previous article

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Telephone

Company Address

Weier Business 801, No. 92 Huai'an East Road, Yuhua District, Shijiazhuang City, Hebei Province