Humidifying Stirring Equipment: Optimizing Your Mixing Solutions for Superior Quality

Feb 21,2026

Humidifying Stirring Equipment: Optimizing Your Mixing Solutions for Superior Quality

Table of Contents

1. Introduction to Humidifying Stirring Equipment

2. What is Humidifying Stirring Equipment?

3. The Importance of Humidifying in Mixing Solutions

4. Types of Humidifying Stirring Equipment

5. Optimizing Your Mixing Solutions: Techniques and Best Practices

6. Technological Advancemen

Humidifying Stirring Equipment: Optimizing Your Mixing Solutions for Superior Quality

Table of Contents

- 1. Introduction to Humidifying Stirring Equipment

- 2. What is Humidifying Stirring Equipment?

- 3. The Importance of Humidifying in Mixing Solutions

- 4. Types of Humidifying Stirring Equipment

- 5. Optimizing Your Mixing Solutions: Techniques and Best Practices

- 6. Technological Advancements in Humidifying Stirring Equipment

- 7. Applications of Humidifying Stirring Equipment in Various Industries

- 8. Common Challenges and Solutions in Using Humidifying Stirring Equipment

- 9. Conclusion

- 10. Frequently Asked Questions (FAQs)

1. Introduction to Humidifying Stirring Equipment

In the world of manufacturing and processing, **mixing solutions** play a vital role in ensuring product quality and consistency. Among the various techniques available, humidifying stirring equipment stands out for its ability to enhance the mixing process. By maintaining optimal moisture levels, this equipment helps achieve superior blending outcomes, particularly in industries dealing with powders, granules, and pastes.

This comprehensive guide will explore the nuances of humidifying stirring equipment and provide insights on how to optimize your mixing solutions effectively.

2. What is Humidifying Stirring Equipment?

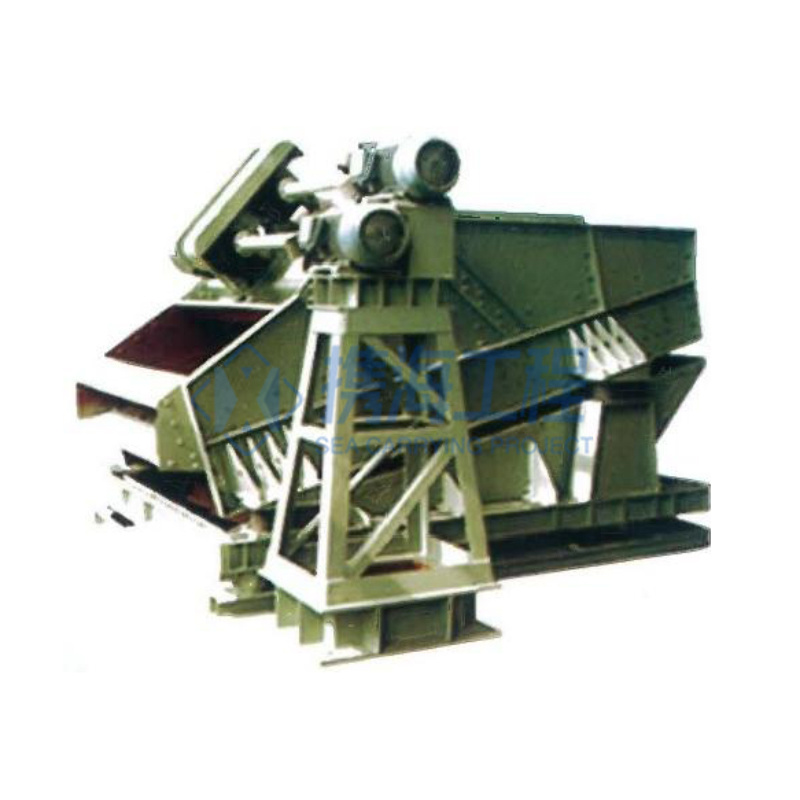

Humidifying stirring equipment refers to specialized machinery designed to mix materials while simultaneously controlling the humidity levels of the ingredients. This dual functionality is crucial for various applications where moisture content influences the behavior of the materials being mixed.

**Key components** of humidifying stirring equipment typically include:

- **Mixing Chamber**: The area where materials are combined and stirred.

- **Humidity Control System**: A mechanism to introduce and regulate moisture within the mixing chamber.

- **Stirring Mechanism**: Various types of agitators that ensure even distribution of materials.

The effectiveness of humidifying stirring equipment is largely dependent on its design and the technologies employed in its construction, which will be delved into further in this article.

3. The Importance of Humidifying in Mixing Solutions

Maintaining an optimal level of moisture during the mixing process is essential for several reasons:

- **Preventing Clumping**: Materials that are too dry can clump together, leading to uneven mixing and affecting the final product's quality.

- **Enhancing Flowability**: Proper humidity improves the flow characteristics of powders, allowing for smoother processing.

- **Improving Product Consistency**: Moisture control ensures that each batch of product has consistent properties, which is crucial for quality assurance.

Understanding the significant impact of humidity on mixing solutions can help manufacturers implement better practices and improve overall productivity.

4. Types of Humidifying Stirring Equipment

There are several types of humidifying stirring equipment, each designed for specific applications and industries. Here are some common variants:

4.1 Continuous Humidifying Mixers

Continuous humidifying mixers are designed for ongoing operations, allowing for constant input and output of materials. These machines are ideal for large-scale production environments where efficiency and consistency are paramount.

4.2 Batch Humidifying Mixers

Batch humidifying mixers are used for smaller quantities of materials, making them suitable for specialized applications or when working with unique formulations.

4.3 High-Shear Mixers

High-shear mixers utilize intense mechanical shear to break down materials while simultaneously introducing moisture, ensuring a uniform mixture and improved homogeneity.

4.4 Planetary Mixers

Planetary mixers are equipped with multi-directional stirring mechanisms, allowing for thorough mixing of viscous and heavy materials while controlling humidity levels.

Understanding the different types of humidifying stirring equipment can guide manufacturers in selecting the right machinery for their specific needs.

5. Optimizing Your Mixing Solutions: Techniques and Best Practices

To achieve the best results with humidifying stirring equipment, manufacturers should consider implementing the following techniques:

5.1 Calibration of Humidity Levels

Regular calibration of humidity control systems ensures that moisture levels remain within the desired range throughout the mixing process. This can significantly improve the quality of the final product.

5.2 Material Preparation

Pre-treating materials by adjusting their moisture levels before mixing can enhance their flowability and mixing efficiency. This preparation step can be especially beneficial for powders and granulated materials.

5.3 Monitoring Mixing Parameters

Employing sensors to monitor mixing speed, temperature, and humidity in real-time allows for immediate adjustments, ensuring optimal mixing conditions.

5.4 Training Operators

Investing in operator training on the proper use of humidifying stirring equipment can lead to better handling and maintenance, ultimately enhancing mixing performance.

By following these best practices, manufacturers can optimize their mixing solutions, resulting in higher-quality products and increased productivity.

6. Technological Advancements in Humidifying Stirring Equipment

As technology evolves, so do the capabilities of humidifying stirring equipment. Recent advancements include:

6.1 Smart Humidifying Systems

Smart humidifying systems utilize IoT technology to provide real-time data and analytics, enabling manufacturers to make informed decisions regarding humidity levels and mixing processes.

6.2 Automation and Robotics

Automation in mixing processes reduces human error and increases consistency. Robotic systems can precisely control humidity levels, mixing speeds, and other parameters.

6.3 Advanced Agitator Designs

Innovative agitator designs enhance mixing efficiency by improving material flow and reducing the energy required for mixing.

These technological advancements enhance the capabilities of humidifying stirring equipment, making them more efficient and effective.

7. Applications of Humidifying Stirring Equipment in Various Industries

Humidifying stirring equipment is widely used across various industries, including:

7.1 Food and Beverage Industry

In the food industry, maintaining specific moisture levels is crucial for product quality and shelf life, making humidifying stirring equipment essential for mixing ingredients.

7.2 Pharmaceutical Manufacturing

Pharmaceutical products often require precise moisture control during mixing to ensure efficacy and compliance with regulations.

7.3 Chemical Processing

Chemical formulations can be sensitive to humidity, necessitating the use of specialized stirring equipment to achieve the desired results.

7.4 Construction Materials

In the construction industry, mixing compounds like cement and mortar requires controlled moisture levels to ensure proper curing and performance.

Understanding the various applications of humidifying stirring equipment can help businesses identify opportunities for implementation in their operations.

8. Common Challenges and Solutions in Using Humidifying Stirring Equipment

Using humidifying stirring equipment can pose certain challenges. Here are some common issues and their solutions:

8.1 Inconsistent Humidity Levels

**Solution**: Regular maintenance and calibration of humidity control systems can help maintain consistent levels.

8.2 Material Degradation

**Solution**: Monitoring mixing times and humidity levels can prevent overheating and degradation of sensitive materials.

8.3 Equipment Wear and Tear

**Solution**: Implementing routine equipment inspections and using high-quality components can minimize wear and prolong equipment life.

By addressing these challenges proactively, manufacturers can enhance the efficiency and effectiveness of their mixing processes.

9. Conclusion

Humidifying stirring equipment plays a crucial role in optimizing mixing solutions across various industries. By understanding the importance of moisture control and implementing best practices, manufacturers can significantly improve product quality and operational efficiency. With ongoing advancements in technology, the future of humidifying stirring equipment looks promising, providing even more opportunities for optimization and innovation.

10. Frequently Asked Questions (FAQs)

What types of materials benefit from humidifying stirring equipment?

Materials such as powders, granules, and viscous pastes benefit significantly from humidifying stirring equipment, as moisture control is essential for achieving optimal mixing outcomes.

How do I determine the optimal humidity level for my mixing process?

The optimal humidity level varies by material and application. Conducting tests and consulting industry guidelines can help determine the appropriate level for your specific needs.

Can humidifying stirring equipment be used for small-scale production?

Yes, batch humidifying mixers are specifically designed for small-scale production and can be effective for unique formulations.

What maintenance is required for humidifying stirring equipment?

Regular inspections, cleaning, and calibration of humidity control systems are essential for maintaining the equipment's performance and longevity.

Are there any industries where humidifying stirring equipment is not used?

While humidifying stirring equipment is beneficial in many sectors, its necessity may vary based on the specific requirements of the materials being mixed. In some cases, traditional mixing methods may suffice.

Previous article