Expert of Systematic Overall Solution for Calcium Material Resource Utilization

-

ProductPioneer In Calcium Material Industry Services, Renowned Globally For Exceptional Quality.Marketing & ServiceNational Service Hotline:

-

SolutionEngineering Service Provider Empowering New Technologies For Calcium Carbonate.Marketing & ServiceNational Service Hotline:

-

CaseExperts In Calcium Stone Industry Engineering With A Deeper Understanding Of Craftsmanship.Marketing & ServiceNational Service Hotline:

-

InnovationSurvive By Quality, Develop Through Innovation.Marketing & ServiceNational Service Hotline:

-

BlogsPeople-Oriented, Advocating Technology, Customer First, Win-Win Cooperation.Marketing & ServiceNational Service Hotline:

-

AboutInnovator In Calcium Materials Industry, Global Service Leader.Marketing & ServiceNational Service Hotline:

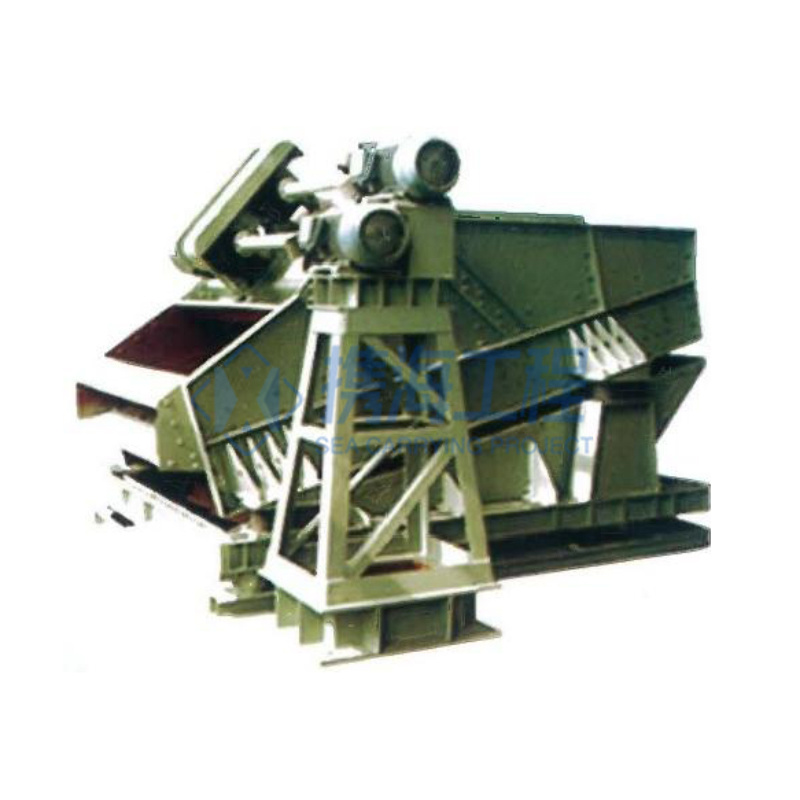

Understanding Mining Vibrating Screens: Essential Insights for Professionals

Feb 14,2026

The fundamental operation of a mining vibrating screen involves a series of movements that encourage particles to move across the screen surface. The vibrations are typically generated by electric motors, which produce a linear or circular motion. This motion helps to stratify the materials, allowing smaller particles to pass through the screen while larger ones remain on top. The effectiveness of a vibrating screen largely depends on factors such as screen design, mesh size, and vibration frequency.

In mining applications, these screens are invaluable for several reasons. First, they improve the overall efficiency of material handling processes. By quickly and accurately separating materials, mining vibrating screens reduce the time and energy required for subsequent processing steps. This not only enhances productivity but also minimizes operational costs, a critical factor in today’s competitive market.

Moreover, mining vibrating screens contribute to the quality of the final product. By ensuring that only adequately sized particles enter the processing phase, they help maintain high standards in the finished materials. This is particularly important in industries where material specifications are stringent, such as in the production of aggregates for construction or high-grade ores for metallurgical processes.

Another significant advantage of mining vibrating screens is their adaptability. They can be tailored to meet the specific requirements of different materials and applications. Whether working with wet or dry materials, or in various environmental conditions, mining vibrating screens can be designed to optimize performance. This versatility makes them a popular choice among professionals in the manufacturing and processing machinery sector.

Additionally, advancements in technology have led to the development of more efficient and durable mining vibrating screens. Innovations such as better screen materials, advanced vibration mechanisms, and improved designs are continually enhancing their performance and lifespan. These developments ensure that mining vibrating screens remain an integral part of modern mining and processing operations.

In summary, mining vibrating screens are essential components that significantly enhance the efficiency and quality of material processing in the mining industry. Understanding their operation and benefits allows professionals to make informed decisions that can lead to improved productivity and lower operational costs. As the industry continues to evolve, staying abreast of these developments will be key for those involved in manufacturing and processing machinery.

Previous article

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Telephone

Company Address

Weier Business 801, No. 92 Huai'an East Road, Yuhua District, Shijiazhuang City, Hebei Province