Expert of Systematic Overall Solution for Calcium Material Resource Utilization

-

ProductPioneer In Calcium Material Industry Services, Renowned Globally For Exceptional Quality.Marketing & ServiceNational Service Hotline:

-

SolutionEngineering Service Provider Empowering New Technologies For Calcium Carbonate.Marketing & ServiceNational Service Hotline:

-

CaseExperts In Calcium Stone Industry Engineering With A Deeper Understanding Of Craftsmanship.Marketing & ServiceNational Service Hotline:

-

InnovationSurvive By Quality, Develop Through Innovation.Marketing & ServiceNational Service Hotline:

-

BlogsPeople-Oriented, Advocating Technology, Customer First, Win-Win Cooperation.Marketing & ServiceNational Service Hotline:

-

AboutInnovator In Calcium Materials Industry, Global Service Leader.Marketing & ServiceNational Service Hotline:

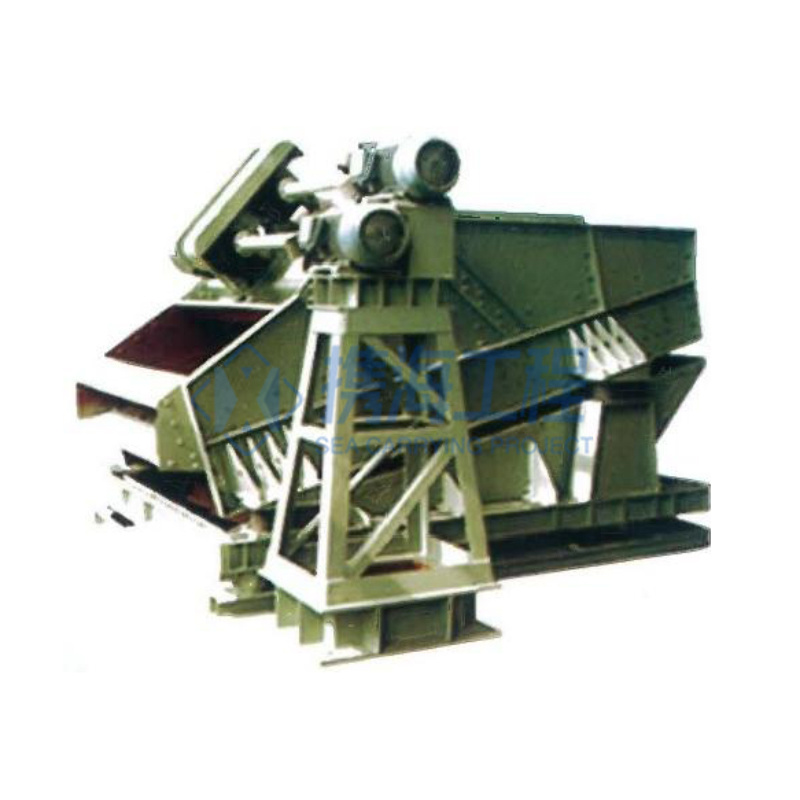

Understanding Mining Vibrating Screens: A Comprehensive Guide for Professionals

Nov 22,2025

At their core, mining vibrating screens consist of a screening surface and a vibration mechanism. The screening surface is typically composed of woven wire, perforated plates, or synthetic materials designed to allow the passage of desired particle sizes while retaining larger particles. The vibration mechanism, often powered by electric motors, generates the necessary movement to keep materials in motion across the screen surface.

One of the primary advantages of mining vibrating screens is their ability to handle a diverse range of materials and particle sizes. Whether dealing with sand, gravel, coal, or other minerals, these screens can be tailored to fit specific operational requirements. Their adjustable frequency and amplitude settings allow for fine-tuning performance based on the material characteristics and desired output.

Moreover, mining vibrating screens are known for their durability and longevity. Constructed from high-quality materials, they can withstand the harsh conditions often found in mining environments, including exposure to abrasive materials and extreme weather conditions. This resilience translates into reduced maintenance costs and increased operational efficiency.

In addition to their basic functionality, modern mining vibrating screens can incorporate advanced technologies to enhance performance. For example, some models feature automated cleaning systems that help maintain screen efficiency by minimizing blockages. Others are equipped with monitoring sensors that provide real-time data on material flow and screen performance, allowing for timely adjustments and improved decision-making.

Applying the right type of mining vibrating screen is vital for achieving optimal results. Professionals must consider factors such as the type of material being processed, desired screening efficiency, and the specific operational environment. It is also important to conduct regular inspections and maintenance to ensure the screens remain in top condition, thereby maximizing productivity and minimizing downtime.

In conclusion, mining vibrating screens are indispensable tools in the manufacturing and processing machinery industry. Their ability to efficiently separate and classify materials, combined with durability and adaptability, makes them essential for various mining applications. By understanding the operational characteristics and benefits of these screens, professionals can make informed decisions that enhance productivity and operational success in their mining endeavors.

Previous article

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Telephone

Company Address

Weier Business 801, No. 92 Huai'an East Road, Yuhua District, Shijiazhuang City, Hebei Province