Expert of Systematic Overall Solution for Calcium Material Resource Utilization

-

ProductPioneer In Calcium Material Industry Services, Renowned Globally For Exceptional Quality.Marketing & ServiceNational Service Hotline:

-

SolutionEngineering Service Provider Empowering New Technologies For Calcium Carbonate.Marketing & ServiceNational Service Hotline:

-

CaseExperts In Calcium Stone Industry Engineering With A Deeper Understanding Of Craftsmanship.Marketing & ServiceNational Service Hotline:

-

InnovationSurvive By Quality, Develop Through Innovation.Marketing & ServiceNational Service Hotline:

-

BlogsPeople-Oriented, Advocating Technology, Customer First, Win-Win Cooperation.Marketing & ServiceNational Service Hotline:

-

AboutInnovator In Calcium Materials Industry, Global Service Leader.Marketing & ServiceNational Service Hotline:

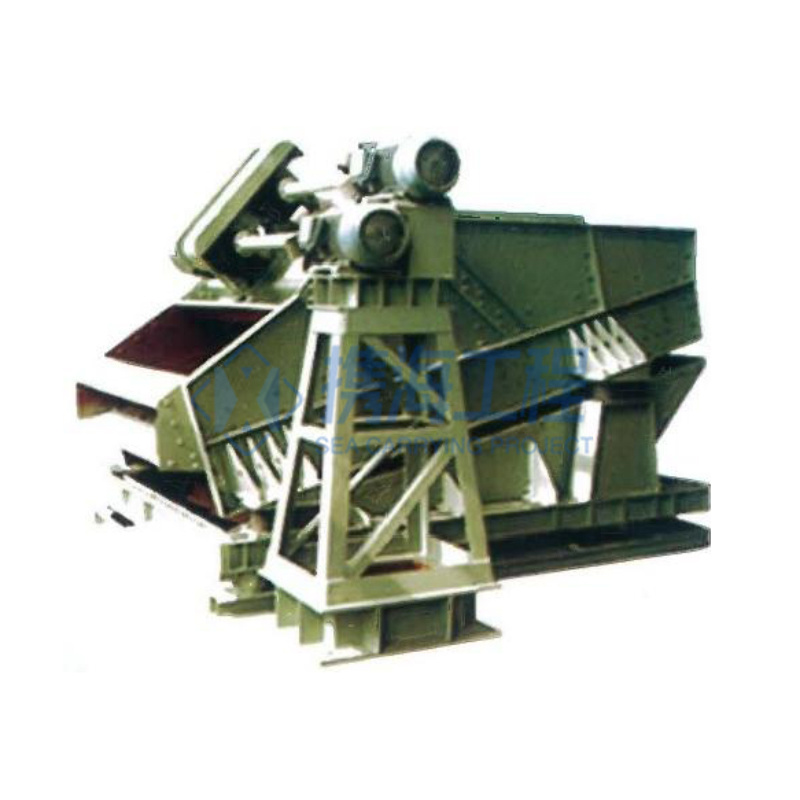

Dust Removal Equipment: Enhancing Air Quality and Industrial Safety

Jan 09,2026

Dust Removal Equipment is a critical component in modern industrial operations, designed to capture, filter, and remove airborne dust and particulate matter from work environments. Industrial processes such as mining, cement production, metal processing, woodworking, chemical manufacturing, and pharmaceuticals often generate large volumes of dust, which can pose significant health risks to workers, reduce equipment efficiency, and contribute to environmental pollution. Dust removal equipment ensures a cleaner, safer, and more compliant workplace while improving overall operational efficiency.

The primary function of dust removal equipment is to separate dust particles from the air. Depending on the application and the type of dust, different technologies are used, including baghouse filters, cartridge collectors, cyclone separators, electrostatic precipitators, and wet scrubbers. Baghouse filters use fabric bags to capture fine particles, offering high filtration efficiency for dry dust. Cartridge collectors employ pleated filter media to handle high airflow and dust loads, suitable for fine, dry dust in manufacturing facilities. Cyclone separators utilize centrifugal force to remove coarse particles from the air stream, ideal for pre-filtration or heavy dust applications. Electrostatic precipitatorscharge particles electrically, attracting them to collector plates, which is highly effective for fine, conductive dust in power plants and chemical industries. Wet scrubbers capture dust by spraying a liquid mist into the air stream, binding particles for removal, especially useful for sticky or hygroscopic dust.

Dust removal equipment improves workplace health and safety by reducing exposure to airborne particulate matter. Dust can cause respiratory issues, skin irritation, and other long-term health problems if not controlled properly. By maintaining clean air, dust removal systems protect workers from inhaling harmful substances, comply with occupational health regulations, and minimize risks of dust-related accidents. For example, in industries handling combustible dust, proper dust collection is essential to prevent explosions, which can be catastrophic in manufacturing or grain handling facilities.

Operational efficiency is another major benefit of dust removal equipment. Dust accumulation on machinery can reduce performance, increase wear and tear, and lead to equipment breakdowns. By capturing dust at the source, these systems maintain cleaner equipment, reduce maintenance requirements, and extend machine lifespan. Furthermore, dust removal improves product quality in manufacturing processes where contamination must be minimized, such as in pharmaceuticals, food processing, and electronics manufacturing.

Energy efficiency and system design are critical considerations for dust removal equipment. Modern systems are designed to optimize airflow, reduce pressure drop, and maintain high filtration efficiency while minimizing energy consumption. Components like fans, ductwork, and filter cleaning mechanisms are engineered for long-term reliability and minimal maintenance. Many systems include automated monitoring and control, allowing operators to track filter performance, airflow, and dust collection levels, ensuring consistent operation and reducing downtime.

Dust removal equipment is versatile and can be customized for specific industrial needs. Modular designs allow for scalable solutions, whether for a single machine, an entire production line, or large industrial facilities. Materials of construction, such as stainless steel, carbon steel, or specialized coatings, are selected based on the chemical properties, temperature, and abrasive nature of the dust. Noise reduction, explosion-proof designs, and compact layouts further enhance the safety and practicality of these systems in challenging industrial environments.

Overall, dust removal equipment is an essential investment for any facility where dust is generated. It protects workers, preserves equipment, ensures regulatory compliance, and enhances overall operational efficiency. By incorporating advanced filtration technologies, ergonomic design, and automated controls, modern dust removal systems provide a reliable, safe, and sustainable solution for maintaining clean air and a healthy work environment across a wide range of industries.

Previous article

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Telephone

Company Address

Weier Business 801, No. 92 Huai'an East Road, Yuhua District, Shijiazhuang City, Hebei Province