The Environmental Benefits of Using Humidifying Stirring Equipment

Jan 10,2026

The Environmental Benefits of Using Humidifying Stirring Equipment

Introduction: The Role of Humidifying Stirring Equipment in Modern Manufacturing

In the rapidly evolving landscape of industrial manufacturing, efficiency and sustainability have become paramount. One significant advancement that has emerged is the use of **humidifying stirring equipment**. This technology not only optimizes pr

The Environmental Benefits of Using Humidifying Stirring Equipment

Introduction: The Role of Humidifying Stirring Equipment in Modern Manufacturing

In the rapidly evolving landscape of industrial manufacturing, efficiency and sustainability have become paramount. One significant advancement that has emerged is the use of **humidifying stirring equipment**. This technology not only optimizes production processes but also offers substantial environmental benefits. In this article, we will delve into the various ways that humidifying stirring equipment contributes to a greener planet, emphasizes its importance in reducing waste, and enhances overall productivity.

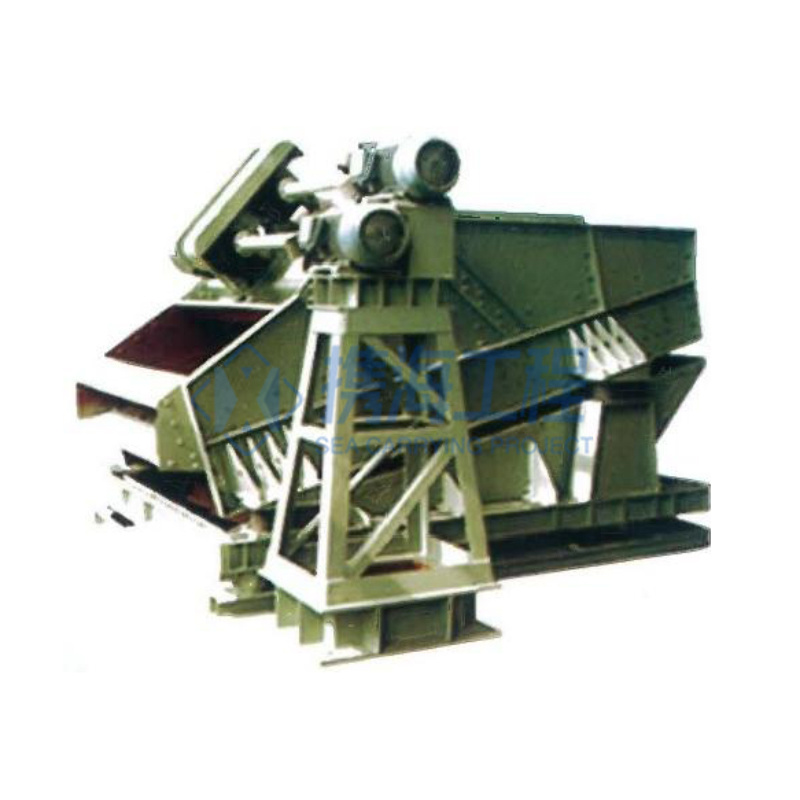

Understanding Humidifying Stirring Equipment

Humidifying stirring equipment is designed to maintain optimal moisture levels in various materials during processing. This technology is particularly beneficial in industries such as food production, pharmaceuticals, and chemical manufacturing, where maintaining specific moisture content is critical for product quality and safety.

The Mechanism of Humidifying Stirring Equipment

At its core, humidifying stirring equipment combines stirring mechanisms with humidity control systems. These systems typically employ a **water vaporization** process to introduce moisture into the mix without altering the physical characteristics of the materials. The result is a homogenous blend that retains essential properties, ultimately leading to enhanced product quality.

Types of Humidifying Stirring Equipment

There are several types of humidifying stirring equipment available, each designed for specific applications:

- **Batch Mixers**: Ideal for small-scale production, these mixers ensure even distribution of moisture within a limited volume.

- **Continuous Mixers**: Used in larger operations, continuous mixers maintain a steady flow of materials while controlling humidity.

- **High-Shear Mixers**: These mixers are effective for creating emulsions and suspensions, where precise moisture levels are crucial.

The Environmental Impacts of Humidifying Stirring Equipment

Integrating humidifying stirring equipment into manufacturing processes can yield numerous environmental benefits, which we will explore in detail.

1. Energy Efficiency and Reduced Consumption

One of the primary advantages of humidifying stirring equipment is its ability to enhance energy efficiency. By maintaining optimal moisture levels, these systems reduce the need for additional heating or cooling, leading to significant energy savings. Industries that adopt this technology can lower their energy consumption, which contributes to a decrease in greenhouse gas emissions.

2. Waste Reduction through Improved Product Quality

Humidifying stirring equipment helps minimize waste by ensuring consistent product quality. When moisture levels are controlled accurately, there is less risk of spoilage or defects, leading to fewer materials wasted during production. This not only conserves resources but also reduces the environmental burden associated with waste disposal.

3. Enhanced Recycling Opportunities

By improving the quality of the final product, humidifying stirring equipment can facilitate recycling efforts. Materials that meet specific quality standards can more easily be reprocessed or repurposed, further reducing the overall environmental impact. This encourages a circular economy where resources are reused rather than discarded.

4. Lower Emissions and Improved Air Quality

Using humidifying stirring equipment can lead to lower emissions of volatile organic compounds (VOCs) and other pollutants. When humidity is regulated, the likelihood of dust and particulate matter being released into the air decreases. This results in improved air quality both within manufacturing facilities and in surrounding communities.

5. Contribution to Sustainable Practices

Adopting humidifying stirring equipment aligns with broader sustainable manufacturing practices. Companies that prioritize environmentally friendly technologies can enhance their brand reputation and appeal to eco-conscious consumers. This can lead to increased market share and customer loyalty as businesses demonstrate their commitment to sustainability.

The Economic Benefits of Investing in Humidifying Stirring Equipment

In addition to environmental advantages, humidifying stirring equipment offers several economic benefits that can make a compelling case for its adoption.

Cost Savings through Efficiency

While the initial investment in humidifying stirring equipment may seem significant, the long-term savings can be substantial. Reduced energy consumption, lower waste production, and improved product quality all translate into cost savings that can offset the initial expenditure.

Competitive Advantage in the Market

By utilizing cutting-edge technology like humidifying stirring equipment, companies can gain a competitive edge. Offering higher-quality products that meet environmental standards can help attract new customers and retain existing ones.

Regulatory Compliance and Incentives

As environmental regulations become stricter, investing in humidifying stirring equipment can ensure compliance and avoid potential fines. Furthermore, many governments offer incentives for businesses implementing sustainable technologies, providing additional financial benefits.

Challenges and Considerations in Implementing Humidifying Stirring Equipment

While the advantages of humidifying stirring equipment are compelling, there are challenges and considerations to keep in mind during implementation.

1. Initial Capital Investment

The cost of acquiring and installing humidifying stirring equipment can be a barrier for some companies, particularly smaller businesses. However, understanding the long-term benefits can help justify the investment.

2. Training and Adaptation

Employees may require training to effectively operate and maintain the new equipment. This adaptation period can impact productivity in the short term, but investing in proper education will yield long-term benefits.

3. Maintenance and Upkeep

Like any machinery, humidifying stirring equipment requires regular maintenance to ensure optimal performance. Establishing a maintenance schedule is essential to prolong the lifespan of the equipment and maintain efficiency.

Future Trends in Humidifying Stirring Technology

As technology continues to evolve, we can expect further advancements in humidifying stirring equipment that will enhance its capabilities and environmental benefits.

1. Integration with IoT and Smart Technologies

The integration of Internet of Things (IoT) technology may lead to more sophisticated humidifying stirring systems capable of real-time monitoring and adjustments. This could optimize moisture management further and improve energy efficiency.

2. Improved Materials and Design

Future developments may also include the use of advanced materials that enhance durability and reduce maintenance needs. Ergonomic designs could facilitate easier operation and improve user experience.

3. Expanding Applications Across Industries

As industries become more aware of the environmental benefits, we can anticipate an increase in the adoption of humidifying stirring equipment across various sectors beyond traditional applications.

Conclusion: Embracing Humidifying Stirring Equipment for a Greener Future

The use of humidifying stirring equipment presents a promising opportunity for manufacturers to enhance their sustainability efforts. Through energy efficiency, waste reduction, and improved product quality, this technology not only benefits the environment but also supports economic growth. By embracing these advancements, businesses can contribute to a cleaner, greener future while meeting the demands of an increasingly eco-conscious market.

FAQs

1. What industries benefit the most from humidifying stirring equipment?

Humidifying stirring equipment is particularly beneficial in food production, pharmaceuticals, and chemical manufacturing, where moisture control is critical.

2. How does humidifying stirring equipment improve energy efficiency?

By maintaining optimal moisture levels, these systems reduce the need for excessive heating or cooling, leading to lower energy consumption.

3. What are the initial costs associated with humidifying stirring equipment?

Initial costs can vary, but companies should consider the long-term savings in energy and waste reduction when evaluating their investment.

4. Can humidifying stirring equipment help in complying with environmental regulations?

Yes, by adopting this technology, companies can enhance compliance with environmental standards and avoid potential fines.

5. Will employees need to be trained to operate humidifying stirring equipment?

Yes, proper training is essential to ensure efficient operation and maintenance of the equipment, ultimately maximizing its benefits.