Expert of Systematic Overall Solution for Calcium Material Resource Utilization

-

ProductPioneer In Calcium Material Industry Services, Renowned Globally For Exceptional Quality.Marketing & ServiceNational Service Hotline:

-

SolutionEngineering Service Provider Empowering New Technologies For Calcium Carbonate.Marketing & ServiceNational Service Hotline:

-

CaseExperts In Calcium Stone Industry Engineering With A Deeper Understanding Of Craftsmanship.Marketing & ServiceNational Service Hotline:

-

InnovationSurvive By Quality, Develop Through Innovation.Marketing & ServiceNational Service Hotline:

-

BlogsPeople-Oriented, Advocating Technology, Customer First, Win-Win Cooperation.Marketing & ServiceNational Service Hotline:

-

AboutInnovator In Calcium Materials Industry, Global Service Leader.Marketing & ServiceNational Service Hotline:

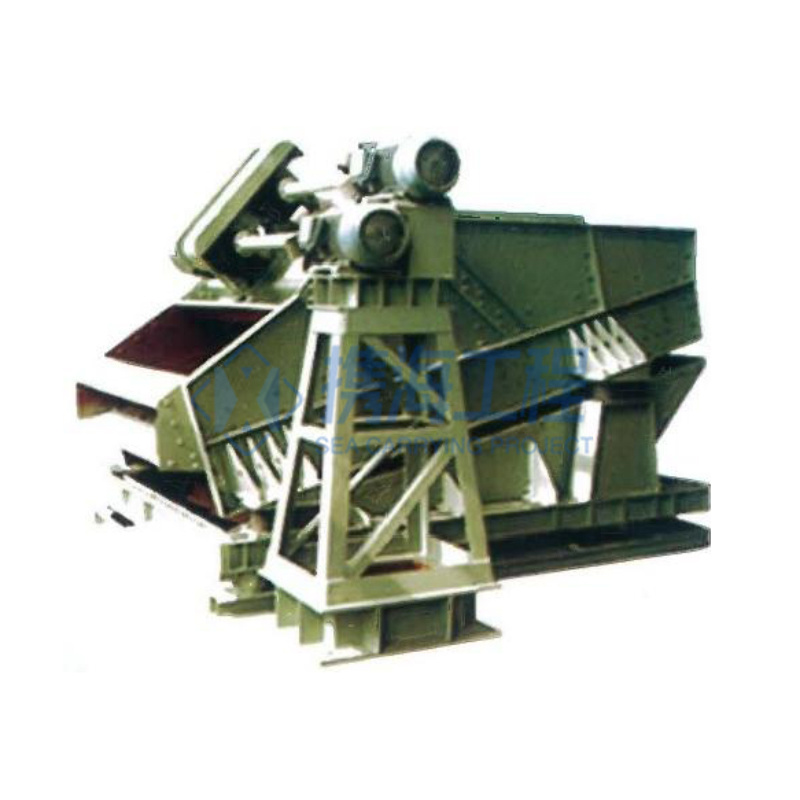

Understanding Conveying Equipment: A Comprehensive Guide for Industrial Applications

Dec 20,2025

At its core, conveying equipment encompasses a range of devices designed to move items from one location to another. The most common types include belt conveyors, roller conveyors, screw conveyors, and chain conveyors. Each type serves a specific purpose and is selected based on the material being transported, the distance it needs to cover, and the required speed of operation.

Belt conveyors are among the most widely used conveying equipment due to their versatility and efficiency. They consist of a continuous loop of material that carries items along a designated path. This type is particularly effective for transporting bulk materials, such as grains, coal, and aggregates, as well as packaged goods in warehouses.

Roller conveyors, on the other hand, utilize a series of rollers to move items. This design is ideal for handling heavier loads and is often employed in shipping and receiving applications. The ease of loading and unloading on roller conveyors makes them a popular choice for operations that require frequent handling.

Screw conveyors are designed for transporting bulk materials in a horizontal or inclined manner. They utilize a rotating helical screw blade that moves materials along a trough. This type of conveying equipment is particularly useful for moving powders, granules, and other bulk materials in industrial settings.

Chain conveyors offer a robust solution for transporting heavy items or pallets. These systems utilize chains to provide a stable and secure means of moving loads, making them suitable for assembly lines and manufacturing processes.

The benefits of incorporating conveying equipment into industrial operations are manifold. Primarily, they enhance productivity by reducing manual labor and minimizing the risk of product damage during transport. Additionally, these systems improve workflow efficiency by enabling a continuous flow of materials, which is vital in fast-paced environments.

Moreover, modern conveying equipment can be integrated with automation technologies, allowing for increased control and monitoring. This integration aids in optimizing performance, reducing downtime, and enhancing overall operational effectiveness.

In conclusion, understanding the various types and functions of conveying equipment is essential for making informed decisions in industrial settings. By selecting the appropriate system for specific applications, businesses can significantly improve their operational efficiency and productivity. Emphasizing the importance of these systems in the manufacturing and logistics sectors highlights their critical role in the success of industrial operations.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Telephone

Company Address

Weier Business 801, No. 92 Huai'an East Road, Yuhua District, Shijiazhuang City, Hebei Province